The Throughline Between Engineering Education and Healthcare Access

With costs skyrocketing, healthcare facilities need a full pipeline of trained engineers to keep their doors open to all.

U.S. hospital prices have gone up more than 250% in the last 25 years. Facility teams are critical in the fight to keep operational costs down and healthcare accessible. But what happens when there aren’t enough operators to do this vital work?

The Importance of the Operational Pipeline to Affordable Healthcare

Healthcare prices are so high today that 29 million Americans cannot afford or access good healthcare. And as we all know, costs will only continue to mount due to:

- Improvements in medical technology (including pharmaceuticals),

- Lack of price transparency to consumers, and

- Decreasing competition for care as provider groups and related healthcare offerings merge or consolidate.

The gist is that healthcare facilities need support to keep a lid on spiraling costs. At utiliVisor, we put our money where our mouth is, donating $250,000 to the healthcare facility that’s not only a client but the closest hospital to all four Angerame households, Valley Hospital, to help ensure quality healthcare is available not only for us but our entire community.

But sustaining a hospital long-term takes more than donations. We as an industry have to take a holistic view.

Here's what we mean: Operational efficiencies are essential to help compensate for rising medical costs. To achieve those efficiencies, we need facility professionals who have both the technical skills and business acumen to identify and maintain savings without impacting patient care. And to do that, we need an educational system that can consistently train new engineers in all the skills required. As we all know, that pipeline is currently far from full.

Here’s how the operations pipeline used to work: Specialized schools like SUNY Maritime College provided students with hands-on operations education. On the job, robust corporate programs developed the business and management skills engineers needed to move up the job ladder so they could act as that all-important conduit between plant and boardroom. But those development programs have largely vanished, creating a skills vacuum just as experienced engineers approach retirement – the so-called “silver tsunami.”

Fixing the Pipeline Leaks

What can be done to keep a full roster of engineering experts? For that perspective, we talked to our president, Richard Angerame, and our client and fellow Maritime alum Joe Lorino, VP of facilities management at Valley Hospital, about where time, effort, and money make a real difference.

Both men pointed out the significance of education in setting young engineers up for career success. “I attribute my success to my connection with Maritime and other alums like Richard and his sons,” Lorino said. “We both continue to support Maritime 40–50 years later because we want to pay back the school for what it gave us. Whether it’s monetary contributions or mentoring, it’s very important to me to give back. What differentiates Maritime is the hands-on experience the students receive. Two months of the year, the cadets are actually operating the training ship. And with operations comes maintenance. Because when you’re in the middle of the ocean, you can’t just run out to Home Depot for parts. They have to repair the equipment and sometimes even fabricate the parts.

“Maritime has built new labs that allow the students to learn how to weld, new labs that allow them to machine shop, fabricate parts out of a piece of metal, and then labs that will enable you to operate and maintain boilers, chillers, air handlers, whatever it may be. And those labs are a result of contributions made mostly by alumni,” Lorino said. That practical experience is precisely what both Angerame and Lorino want so that students can grow and prosper as engineers and as business professionals.

“Maritime puts out great engineers,” said Angerame. “But graduates don’t get the management and business training they need, now that corporate training programs have fallen out of favor. Then sometimes Maritime engineering grads plateau in their careers and walk away. We need to make sure the student is getting the education they need to support themselves beyond the degree and that first job. We need to give them the skills to grow and so that they have the funds down the road when they get older, like us, so that they can start donating dollars back. It’s a way to keep the school, as well as the job pipeline, sustainable.”

How the Pipeline Supports Healthcare Access

How does supporting engineering education support healthcare? “Healthcare is an increasingly tough business. Costs are always going up, and hospitals can’t operate on Medicare payments alone,” Angerame pointed out. “By us keeping control of the utility plant operating costs, we can offset deficits. We become an important part of what infrastructure is needed and what doesn’t have to be built or purchased.”

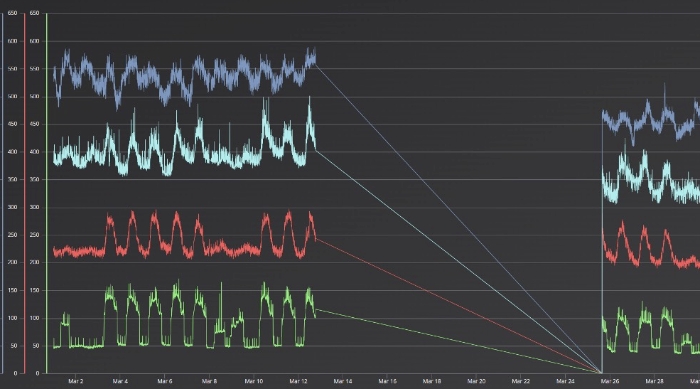

We’ve been working with Valley Hospital to successfully apply and receive state and local funding incentives in the $millions, and that goes a long way to support the hospital’s mission. But how does operational efficiency show up in Valley’s day-to-day ledger?

“When you’re caring for a patient,” Lorino noted, “you can’t sacrifice anything. Anything we can do to bring costs down is a win. Even negotiating the cost of toilet paper leads to more funding going toward patient care.”

Lorino shares his uncompromising drive to find cost savings with Valley’s CEO, Dr. Rob Brenner, and its Systems CEO Emeritus, Audrey Meyers. Their results speak for themselves. “We're about 16 percent more efficient than another hospital building of similar size, so there's a big reduction in energy there, which then means a reduction in carbon emissions because there's less energy needed to cool and heat. It all leads to a better healing environment for our patients,” said Lorino.

How to Reduce Healthcare Operating Costs AND Support the Skills Pipeline

The energy challenges facing healthcare must continue to be met by innovative operations professionals at every level, from boiler maintenance to vice president, or too many communities will go without access to the healthcare they need. The challenge facing specialized institutions like Maritime isn't just about producing innovative young and hands-on engineers. It's about cultivating student leadership skills and business experience, so that those new engineers have the expertise for long-term success and a path to give back to the communities and schools that made that success possible.

Producing experienced engineers like SUNY Maritime graduates and then making sure those engineers also receive an education in business is what hospital CEOs really need to keep a lid on operating costs. Without such a self-supporting pipeline, our industry can’t do our part to reduce healthcare operating costs, to everyone’s detriment.

You Might Like

About utiliVisor

Your tenant submetering and energy plant optimization services are an essential part of your operation. You deserve personalized energy insights from a team that knows buildings from the inside out, applies IoT technology and is energized by providing you with accurate data and energy optimization insights. When you need experience, expertise, and service, you need utiliVisor on your side, delivering consistent energy and cost-saving strategies to you. What more can our 45+ years of experience and historical data do for you? Call utiliVisor at 212-260-4800 or visit utilivisor.com