Real-Time Monitoring: How We Caught a Set Point Problem Before It Became Expensive

A compressor suddenly went off the rails. But why?,_rooftop_HVAC.jpg/jcr:content/AHU%20hanging%20from%20a%20crane_1024px-130420-F-ZZ999-101_(15718415681),_rooftop_HVAC.jpg)

It’s a tale as old as time. You make a change to fix a problem. And it does fix it, at least partially or temporarily. But because operations systems are really, really complicated, your fix accidentally kicks off some other, unintended consequence that you may or may not notice right away. Now you have two problems.

Here’s the story of one such situation and how building data revealed it.

Free Cooling That Wasn't "Free"

The start of every work day for an engineer at utiliVisor is the same: grab a cup of coffee (or three, if you’re Tim, our COO) and pull up your clients’ data to see if there’s anything small but unusual going on. No news is good news, of course. But if anything is going south, we prefer to find it early, while it's easier and cheaper to solve.

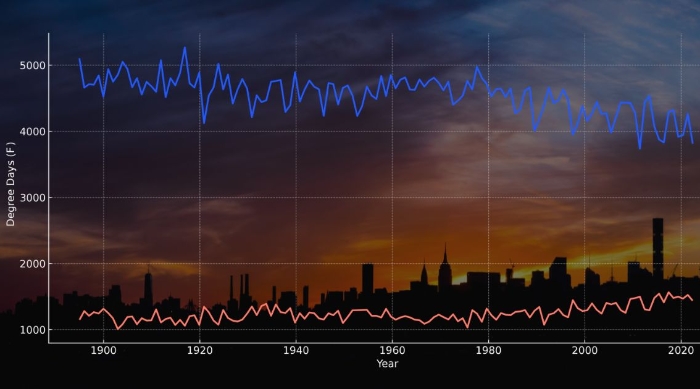

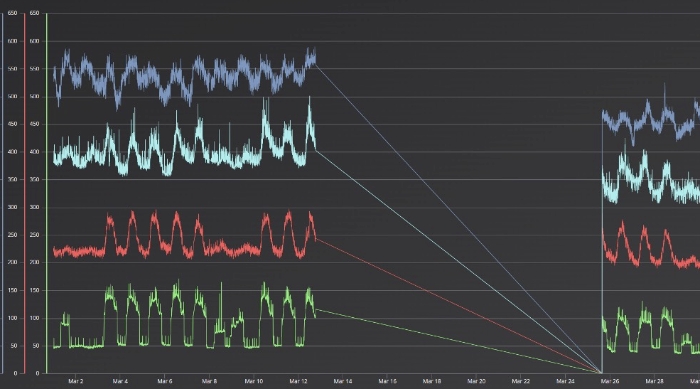

This particular day, our VP of operations, Chris Angerame, spotted a change in the demand for an air handling unit (AHU). The normal pattern for this unit was to cycle on and off as needed to meet set point. So Chris looked at the local weather data to see if that explained what he was seeing. Nope, it wasn’t really all that hot out, so weather didn’t explain what he was seeing. So what was driving the compressor to run flat out?

Next, Chris pulled up the set-point data. Turned out the set point for this particular AHU was much higher than all the other AHUs.

The change in the set point explained the change in demand. The compressor was going full out. It was going to meet that set point, by any means necessary.

Of course, the “means” is more power and non-stop operation. $$$

Chris reached out to alert the on-site team and have them confirm what the meter and sensor data was saying.

Turned out, the facility team had been having problems with an economizer coil (aka the “free cooling valve”). The valve for this unit wasn't opening properly. To address the valve issue, the team had changed the set point to force the valve open.

But sometimes/much of the time, equipment doesn't do what you expect. In this case, the change to the set point both didn’t quite fix the valve issue AND it pushed the compressor into continuous operation.

Is this issue a big deal? By itself, no. But just as a kitchen remodel is a battle of inches, maintaining your operations targets is a battle of small actions that keep your demand down and protect the lifespan of hard-working and expensive equipment.

Costs Add Up. So Do Savings.

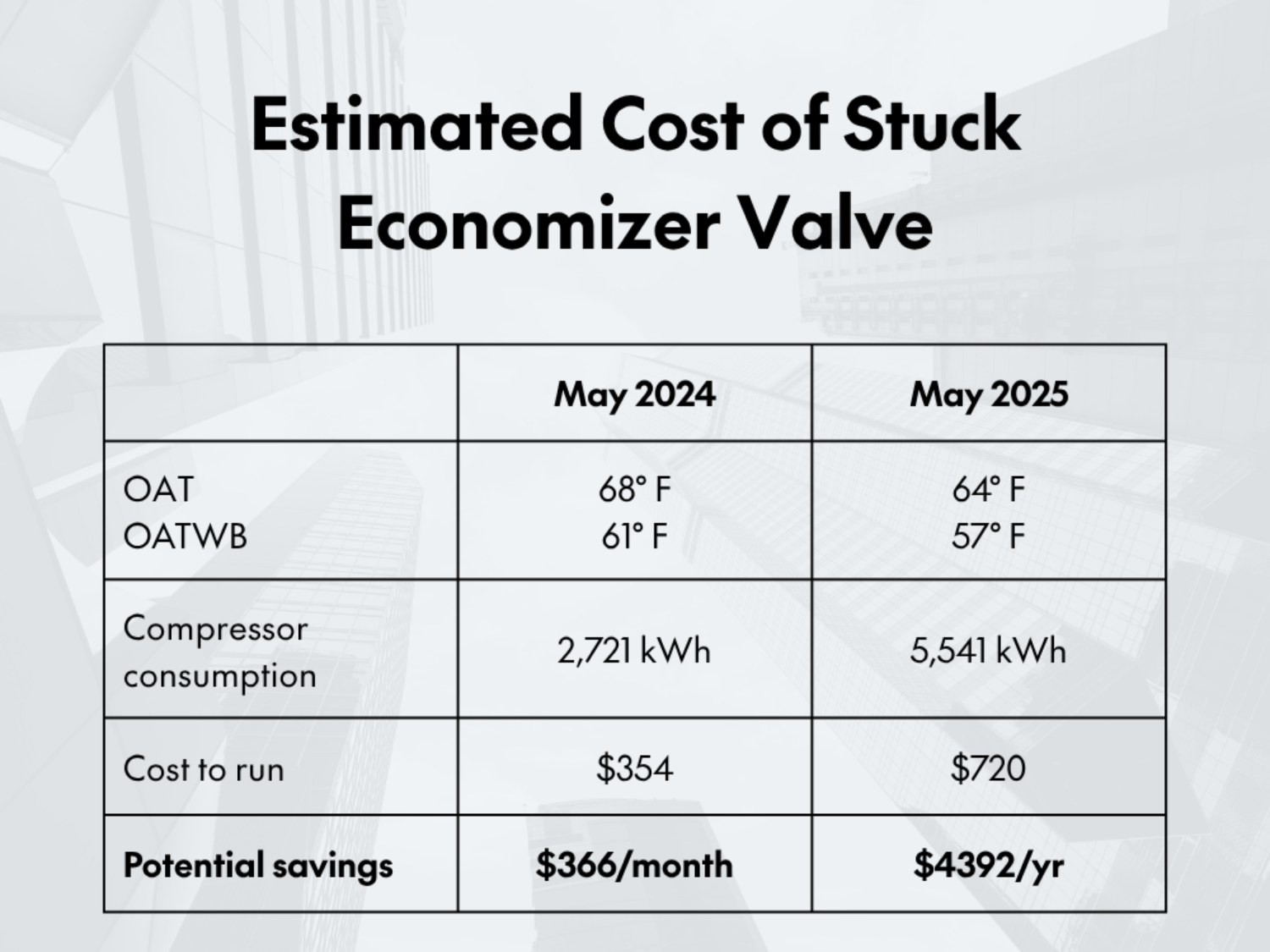

The savings on continuous compressor operation aren't huge, but they do add up. Here’s the math on what this one little issue could have cost if it hadn’t been caught quickly.

Note that we’ve normalized for temperature to compare AHU data from last year to this year.

Key Takeaway

Regular monitoring of equipment demand patterns can reveal hidden inefficiencies. Unexpected changes in patterns are a red flag. Prompt attention to operational anomalies like this compressor change is the difference between hitting your numbers once and maintaining them over time, not to mention extending the life of your equipment.

You Might Like

About utiliVisor

Your tenant submetering and energy plant optimization services are an essential part of your operation. You deserve personalized energy insights from a team that knows buildings from the inside out, applies IoT technology and is energized by providing you with accurate data and energy optimization insights. When you need experience, expertise, and service, you need utiliVisor on your side, delivering consistent energy and cost-saving strategies to you. What more can our 45+ years of experience and historical data do for you? Call utiliVisor at 212-260-4800 or visit utilivisor.com